How Does a Condenser Dryer Work: A Complete Guide

Condenser dryers have become one of the most popular laundry appliances in modern homes, especially where venting to the outside isn’t practical. Instead of blowing warm, moist air outdoors (like a vented dryer), a condenser dryer cleverly removes moisture internally, collecting water in a tank or sending it away via a drain hose.

This post breaks down every major component, explains what happens at each stage, and compares condenser dryers with heat-pump and vented alternatives.

1.The Purpose of a Condenser Dryer

A traditional vented tumble dryer removes moisture by heating air, passing it through your clothing, and venting the humid air outside.

A condenser dryer, by contrast:

- Does not require external venting

- Works in any room with adequate ventilation

- Collects water internally

- Is typically more efficient than vented dryers (but less efficient than heat-pump dryers)

The key technology enabling this is the condenser unit, which extracts moisture from the warm air.

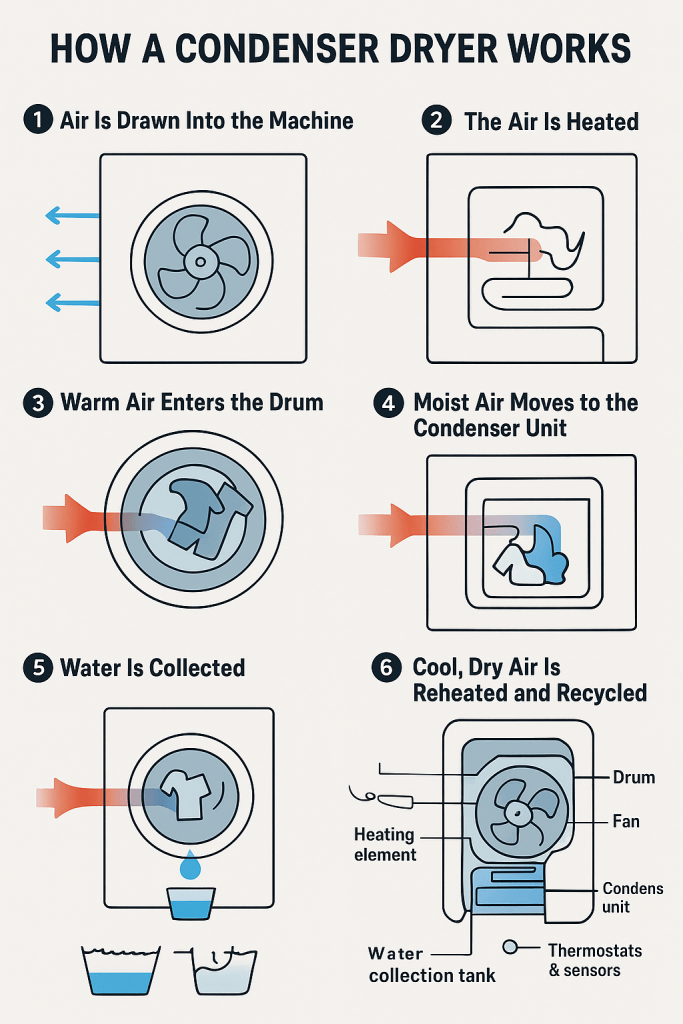

2. The Internal Process — Step by Step

Here’s the full sequence of what happens when you press “Start”.

Step 1 — Air Is Drawn Into the Machine

A fan inside the dryer pulls room-temperature air into the machine.

This fresh air is essential because it will be heated and circulated through your laundry.

Components involved:

- Intake vents

- Internal fan

- Heater unit

Step 2 — The Air Is Heated

Once inside, the air passes over an electric heating element, similar to those used in ovens or fan heaters.

This air is heated to around 50–70°C, depending on the cycle.

Why heat matters:

Warm air evaporates moisture from clothes much more effectively than room-temperature air.

Step 3 — Warm Air Enters the Drum

The hot air flows into the rotating drum containing your wet laundry.

As the drum turns:

- Clothes lift and drop through the warm airflow.

- Moisture inside the fabric evaporates into the air.

- This creates warm, humid air.

- This moisture-rich air is constantly extracted and moved into the condenser unit.

Step 4 — Moist Air Moves to the Condenser Unit

This is the key stage that differentiates a condenser dryer from a vented dryer.

Inside the condenser chamber:

- The hot, moist air flows over cold metal plates or a heat exchanger.

- As the hot air contacts the cold surfaces, the moisture rapidly condenses into liquid water.

- The water droplets drip down into a tray or collection tank.

In simple terms:

The condenser turns steam back into water.

Step 5 — Water Is Collected

After condensation, the water gathers in one of two places:

Option A: Water Tank

Most dryers store the water in a removable tank located at the top or bottom of the machine.

You empty this manually after each cycle.

Option B: Plumbed-in Drain Hose

Some models offer a drainage hose that you can connect to:

- A sink waste

- A washing machine drain

- A dedicated outlet

This means no tank emptying required.

Step 6 — Cool, Dry Air Is Reheated and Recycled

Once humidity is removed:

- The air (now cooler and drier) is reheated

- It is blown back into the drum

- The cycle repeats until the clothes reach the target dryness level

This closed-loop system makes condenser dryers versatile—they don’t rely on external airflow.

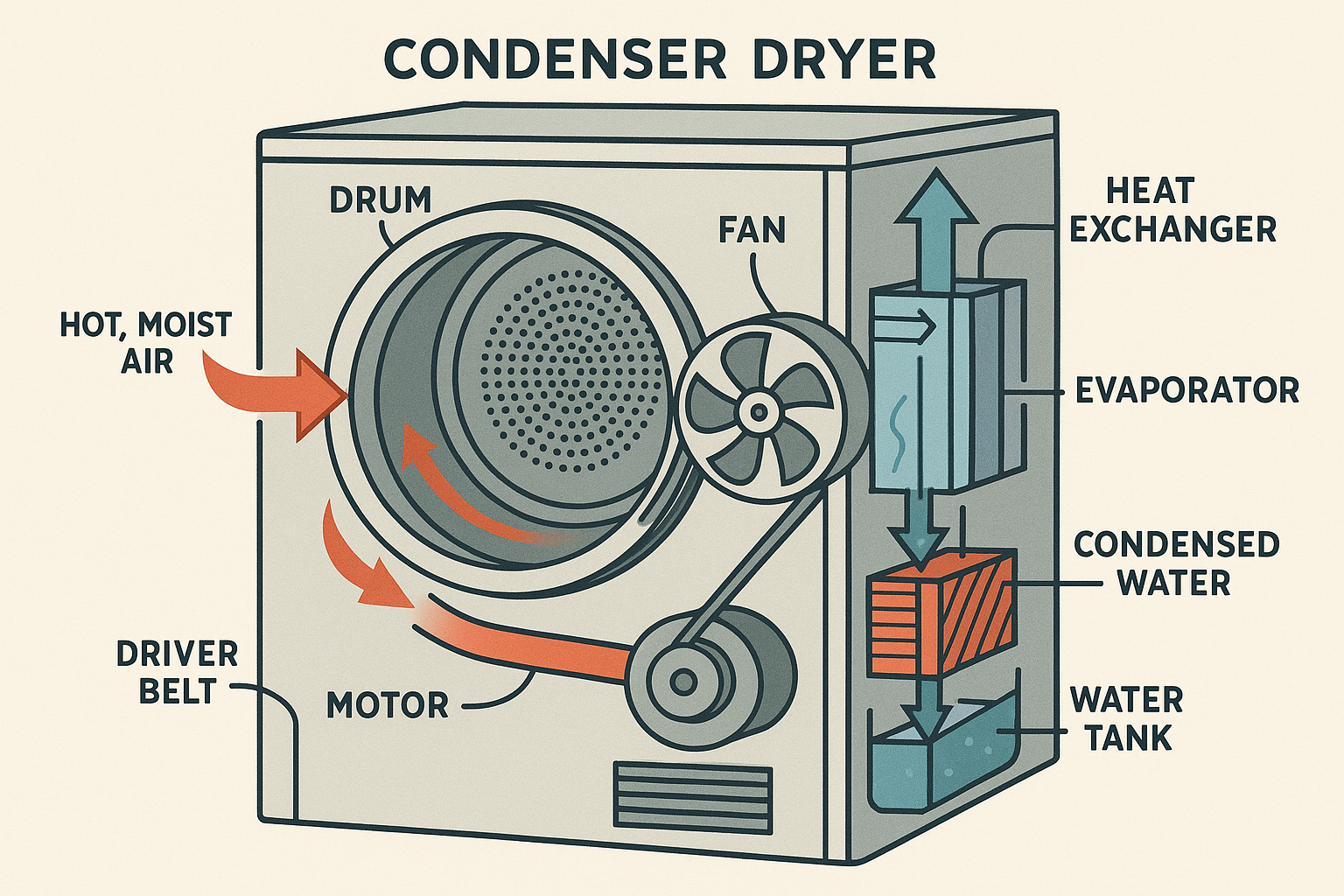

3. How Does A Condenser Dryer Work? – The Key Internal Components Explained

- Drum

The rotating drum tumbles clothes and exposes them to airflow.

- Heating Element

Provides the heat needed to evaporate moisture.

- Fan / Blower Motor

Drives air through the dryer.

- Condenser Unit (Heat Exchanger)

The heart of the system—removes moisture by cooling the hot air.

- Water Collection Tank or Drain Pump

Gathers condensed water.

- Thermostats & Sensors

Prevent overheating and ensure drying stops at the right time.

4. Energy Use and Efficiency

Condenser dryers generally use more electricity than heat-pump models but less than older vented dryers.

Typical energy consumption:

- Condenser dryer: 2.0–4.5 kWh per cycle

- Heat pump dryer: 1.3–2.0 kWh per cycle

- Vented dryer: 3.0–5.0 kWh per cycle

Why condenser dryers consume more energy:

- The heating element must constantly reheat the recycled air

- Heat is lost in the condensation process

5. Pros and Cons of Condenser Dryers

✔️ Advantages

- No external venting required

- Can be installed almost anywhere

- Better performance in cooler environments than heat-pump models

- Faster drying than most heat-pump dryers

- Easy to maintain

❌ Disadvantages

- Higher running costs than heat-pump dryers

- Can warm up the room dramatically

- Requires regular cleaning of condenser unit

- Produces more noise than some alternatives

6. Maintenance Tips for Longevity

To keep your condenser dryer efficient:

After every cycle

- Empty the water tank

- Clean the lint filter

Weekly

- Wipe the door seal

- Check the heat exchanger area

Monthly

- Rinse the condenser unit (when removable)

- Vacuum the vents

Maintenance is crucial—blocked airflow increases fire risk, energy use and drying time.

7. Condenser vs. Heat Pump vs. Vented: Quick Comparison

| Feature | Condenser | Heat Pump | Vented |

|---|

| No external vent needed | ✔️ | ✔️ | ❌ |

| Running cost | Medium | Low | High |

| Drying speed | Fast | Slow–Medium | Fast |

| Ideal location | Anywhere | Warm rooms | Rooms with vent access |

| Price | Moderate | Higher | Lowest |

Conclusion On How Does A Condenser Dryer Work?

A condenser dryer works by heating air, evaporating moisture from your clothes, and condensing that moisture back into water using a clever internal cooling system. It offers excellent flexibility for installation, good drying performance, and simpler setup than vented models—making it a strong choice for modern homes.